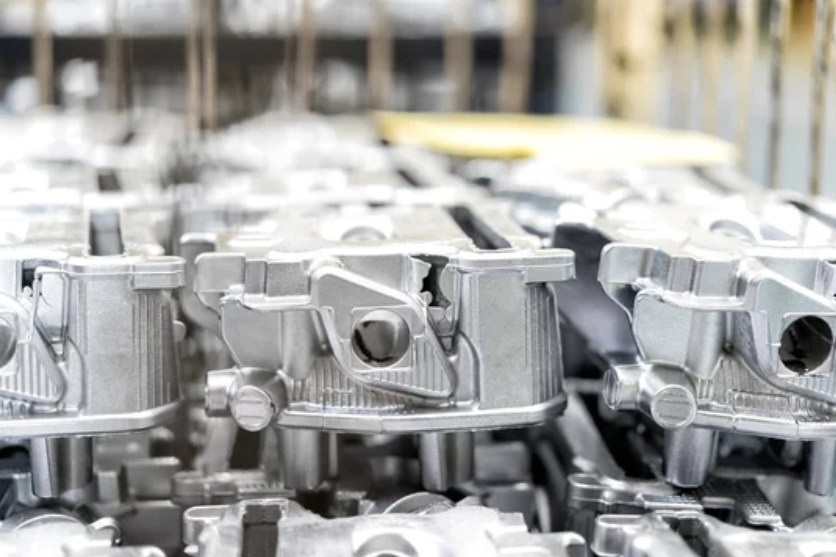

Precision aluminum casting techniques that minimize waste and maximize production efficiency

Wiki Article

A Comprehensive Guide to Picking the Right Foundry Services for Your Job Needs

Selecting the best foundry solutions is necessary for the success of any project. Each spreading method-- sand casting, financial investment spreading, and die casting-- has distinct benefits. Recognizing these choices helps in making notified choices. Product selection, production capabilities, and quality control are essential elements to consider. Furthermore, evaluating prices can impact long-term practicality. Aluminum Foundry. What factors should assist this decision-making procedure?Understanding the Different Types of Foundry Providers

While the globe of foundry solutions might seem complicated in the beginning glance, recognizing the various kinds can substantially enhance the manufacturing procedure. Foundries commonly concentrate on casting metals, and the primary types consist of sand spreading, financial investment casting, pass away spreading, and centrifugal casting.Sand spreading involves creating molds from sand and is excellent for large components or low-volume manufacturing. Financial investment spreading, on the various other hand, supplies high precision for intricate designs, making it suitable for aerospace or clinical applications. Die casting, defined by requiring molten metal right into molds under high stress, is reliable for mass manufacturing of smaller sized components.

Centrifugal spreading utilizes rotational force to distribute molten metal, yielding strong, round components. Each solution type is and has unique advantages selected based on specific project needs. Understanding these distinctions allows makers to select the most ideal shop solution, ultimately boosting performance and item quality.

Key Variables to Think About in Product Selection

Selecting the ideal material for foundry solutions is an important action that affects the overall success of a job. Secret elements in product choice consist of mechanical homes, thermal resistance, and corrosion resistance - Aluminum Foundry. Comprehending the intended application and its needs is vital; products have to endure functional tensions while keeping integrity in timeAnother essential factor to consider is the product's compatibility with the picked production process, as some products are better fit for details techniques. Cost-effectiveness likewise plays a considerable duty, as budget restraints can restrict alternatives.

Lastly, accessibility and lead times of materials can impact project timelines, making it needed for task managers to assess these elements thoroughly. By meticulously examining these elements, one can ensure an extra effective and effective foundry solution experience.

Assessing Production Capacities and Technologies

Just how effectively a factory can meet job specifications hinges on its manufacturing abilities and modern technologies. An extensive analysis of these elements is crucial for job success. Manufacturing abilities incorporate the foundry's capacity to manage varying task sizes, timelines, and complexities. Comprehending the foundry's devices and equipment is essential, as modern innovations such as computer mathematical control (CNC) machining and advanced mold-making strategies can considerably enhance accuracy and efficiency.In addition, the foundry's use ingenious products and processes, such as 3D printing or shed foam casting, can supply advantages pertaining to style adaptability and cost-effectiveness. It is likewise vital to assess the shop's ability to range production, making sure that they can accommodate future boosts in need without compromising top quality. By carefully examining these factors, job supervisors can make informed decisions concerning which shop is best fit to fulfill their specific production demands and technical expectations.

Value of Top Quality Assurance in Metal Casting

Quality control stands as a crucial pillar in the steel spreading market, making certain that every component meets rigid requirements and criteria. This process involves systematic surveillance and assessment of each stage of manufacturing, from first layout to final assessment. Carrying out rigorous quality control protocols improves the reliability and performance of actors elements, lowering the probability of flaws that can endanger architectural honesty.Reliable top quality guarantee cultivates count on between customers and factories, as adherence to high standards signifies dedication to quality. It likewise reduces costly rework and hold-ups, simplifying manufacturing processes. By identifying possible problems early, high quality assurance not just safeguards the end product yet likewise contributes to continuous renovation within the factory's operations. Inevitably, prioritizing quality guarantee in metal spreading is crucial for accomplishing customer satisfaction and keeping a competitive side in the market.

Evaluating Cost-Effectiveness and Spending Plan Restrictions

While traversing the intricacies of foundry solutions, evaluating cost-effectiveness and spending plan restrictions becomes a vital factor for organizations. Understanding the complete cost of possession involves greater than just the preliminary rate; it needs an evaluation of long-term costs, consisting of materials, labor, and functional efficiencies. Business need to request thorough quotes that describe all prospective prices, allowing a more clear contrast between various shops.Additionally, services have to evaluate their certain task requirements against spending plan limitations. This includes examining the compromises in between lower expenses and prospective influence on quality, lead times, and dependability. It is essential to take into account whether the selected factory uses scalable remedies that can accommodate future needs without significant monetary stress. By meticulously stabilizing cost factors with project goals, business can make educated decisions that enhance both budget plan and efficiency, making certain effective end results for their shop tasks.

Regularly Asked Inquiries

Just How Can I Ensure Prompt Distribution of My Shop Task?

What Certifications Should a Shop Provider Have?

A reputable factory provider ought to have qualifications such as ISO 9001 for top quality management, ISO 14001 for environmental monitoring, and industry-specific accreditations that demonstrate conformity with security and performance criteria relevant to the spreading process.

Can I Go To the Foundry Before Choosing?

Yes, going to the shop before choosing is typically suggested. This permits prospective customers to assess the center, meet the team, and warranty that the services line up with their specific job demands and standards.What Is the Normal Lead Time for Customized Castings?

The regular lead time for custom-made spreadings ranges from four to twelve weeks, relying on the complexity of the design, product requirements, and the foundry's capability. Prompt interaction can frequently accelerate the procedure.How Do Factories Manage Layout Changes During Production?

Factories commonly accommodate style modifications throughout manufacturing by implementing flexible processes. They examine the influence on costs and timelines, communicate with clients, and change process to ensure high quality while decreasing disruptions to the production schedule.

Report this wiki page